Due to environmental protection, energy-saving, and the lightness of electric vehicles, electric vehicles have been paid more and more attention by various countries. At present, electric vehicles are in a stage of rapid development. As the core components of electric vehicles, electric vehicle motors mainly include DC motors, AC three-phase induction motors, permanent magnet brushless DC motors, and switched reluctance motors.

1. Brushed DC Motor

The main advantages of brushed DC motors are simple to control and mature technology. It has excellent control characteristics unmatched by AC motors. In the early development of electric vehicles, DC motors are used, and even now, some electric vehicles are still driven by DC motors. However, the existence of brushes and mechanical commutators not only limits the further improvement of the motor’s overload capacity and speed but also requires frequent maintenance and replacement of brushes and commutators if it runs for a long time. In addition, since the loss exists on the rotor, it is difficult to dissipate heat, which limits the further improvement of the motor torque-to-mass ratio. Given the above defects of DC motors, DC motors are not used in newly developed electric vehicles.

2. AC three-phase induction motor

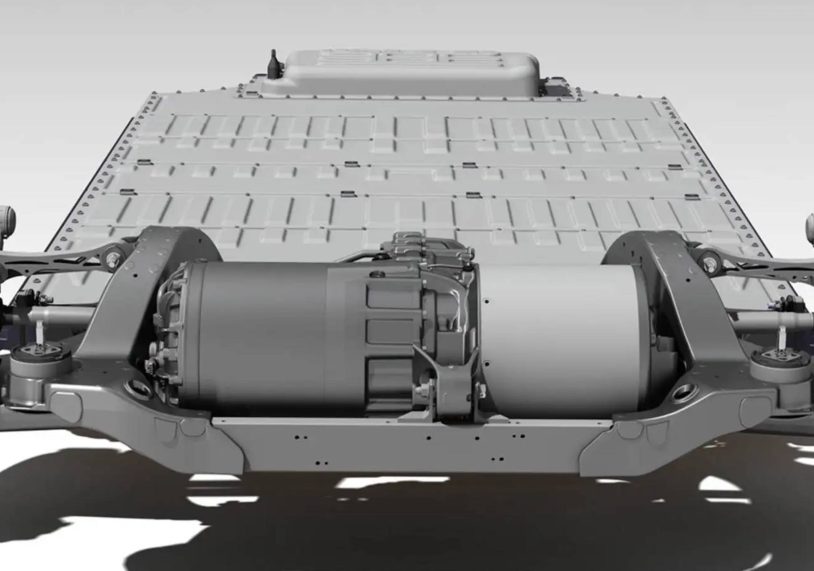

AC three-phase induction motors are the most widely used motors. The stator and rotor are laminated with silicon steel sheets, and there are no slip rings, commutator, and other components in contact with each other between the stators. Simple structure, reliable operation, and durable. The power coverage of the AC induction motor is extensive, and the speed reaches 12000 ~ 15000r/min. Air or liquid cooling can be used with a high degree of cooling freedom. It has good adaptability to the environment and can realize regenerative feedback braking. Compared with the same power DC motor, the efficiency is higher, the quality is reduced by about half, the price is low, and the maintenance is convenient.

3. Permanent magnet brushless DC motor

A permanent magnet brushless DC motor is a high-performance motor. Its most prominent feature is that it has the external characteristics of a DC motor without a mechanical contact structure composed of brushes. In addition, it adopts a permanent magnet rotor, and there is no excitation loss: the heated armature winding is installed on the outer stator, which efficiently dissipates heat. Therefore, the permanent magnet brushless DC motor has no commutation sparks, no radio interference, long life, and reliable operation. Easy maintenance. In addition, its speed is not limited by mechanical commutation. If air or magnetic suspension bearings are used, they can run up to several hundred thousand revolutions per minute. Compared with the permanent magnet brushless DC motor system, it has higher energy density and efficiency and is a good application prospect in electric vehicles.

4. Switched reluctance motor

The switched reluctance motor is a new type of motor. The system has many apparent features: its structure is more straightforward than any other motor, and there are no slip rings, windings, and permanent magnets on the motor’s rotor, but only on the stator. There is a simply concentrated winding, the ends of the winding are short, and there is no interphase jumper, which is easy to maintain and repair. Therefore, the reliability is good, and the speed can reach 15000 r/min. The efficiency can reach 85% to 93%, which is higher than that of AC induction motors. The loss is mainly in the stator, and the motor is easy to cool; the rotor is a permanent magnet, with a wide range of speed regulation, flexible control, easy to achieve various special requirements of torque-speed characteristics and maintain high efficiency in a wide range. It is more suitable for the power performance requirements of electric vehicles.

At present, Tesla, as a leading company in electric vehicle manufacturing, uses three-phase induction motors, while most other electric vehicle manufacturers use permanent magnet brushless DC motors. The reason is not because of three-phase induction motors. The application in electric vehicles is more advanced than the permanent magnet brushless motor, but the asynchronous motor technology used on Tesla has made a significant breakthrough. The biggest drawback of asynchronous motors in the past was that it was difficult to control the rotational speed of the rotor. Still, with the development of modern semiconductor control technology, this problem has been solved. While making breakthroughs, Tesla made good use of the lightweight and small size of AC three-phase induction motors.

Electric vehicles have used different electric motors in different historical periods, and the earliest ones are DC motors with the best control performance and lower cost. With the continuous development of motor technology, machinery manufacturing technology, power electronics technology, and automatic control technology, AC motors, permanent magnet brushless DC motors, and switched reluctance motors show superior performance to DC motors. In electric vehicles, these Electric motors gradually replaced DC motors.